The field of polymer nanocomposites is of rapidly growing interest. Mixing or fusion of polymers with inorganic nanospecies (e.c. nanosilica and clay) can lead to enhanced mechanical properties and improved fire retardancy. Recently, synthesis of particulate or colloidal organic/inorganic hybrids, called core-shell particles has been intensively interested. One of core-shell type, particles-on-a particle has been intensive study in a decade. Most of the studies have been conducted with inorganic solid particles, which are nano-scaled dispersion such as silica with 10nm size. Their nanocomposites in which polymer particles (core) are highly armored by silica particles (sol) have been obtained by the polymerization methods using aqueous alcoholic media, and hydrophilic initiators.

We have realized the novel preparation method using aqueous dispersion polymerization in static condition to synthesize poly(methyl methacrylate, MMA)-silica colloidal composites in which submicron-scale silica particles embedded with the surface of PMMA particles.1,2

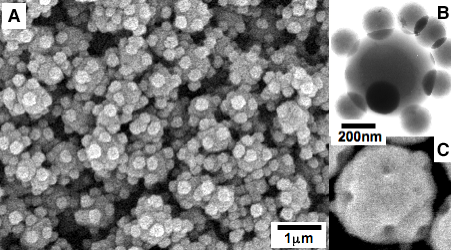

FigureSEM (A and C) and TEM (B) images of Silica/PMMA composite particles (A and B), and PMMA particles after removal of silica (B).

FigureSEM (A and C) and TEM (B) images of Silica/PMMA composite particles (A and B), and PMMA particles after removal of silica (B).

Colloidal milky-white dispersions without polymer coagulation were obtained after the polymerization. Figure A and B shows PMMA/silica composite particles formed by typical dispersion polymerization with 200nm. Massage ball like particles in which some silica particles infrequently adsorbed onto surface of the PMMA particles. Independent PMMA particles were not observed at all. Particle size of the whole composite particles was roughly 700 nm (polydisperse index: 1.19) and the core PMMA particles were estimated as approximately 500nm from DLS measurement. The polymerization methods gave high reproducibility in terms of unique shape, size and dispersion of the composited particles. TEM image confirmed that armored silica particles are embedded with surface of the PMMA particles as shown in Figure B. In addition, TG analysis estimated that average number of the silica particles was ca. 11 for one polymer particle. The result corresponded to the estimated value from TEM images. To remove silica particles, the composite particles were immersed in concentrated KOH solution for above three days. The silica-removed PMMA particles reveals dimple like holes on the particle surfaces, as shown in Figure C. This also proved that the silica particles were embedded with surface of the PMMA particles with certain depth.

In the polymerization process, the polymer particle growth can lead a hetero-coagulation with silica particles to avoid full coagulation of the system by adsorbing of silica as the static stabilizer. The surfaces of silica particles will provide extra charge to secure sufficient electrostatic repulsion between growing polymer particles.

Copyright © 2008- KUNITAKE Laboratory.